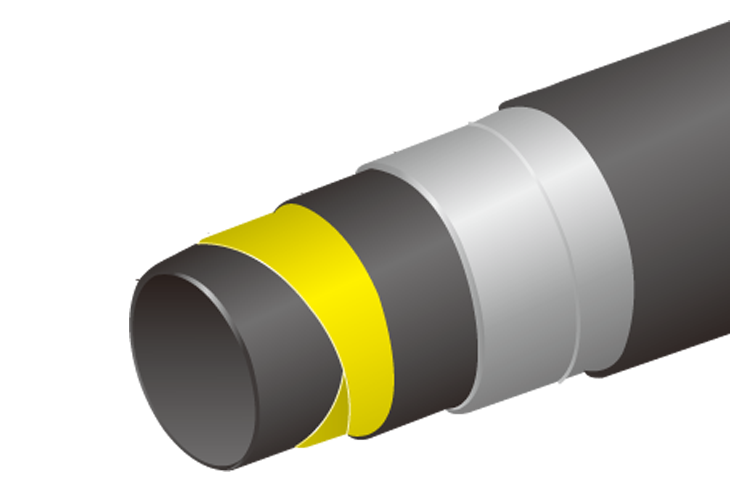

Reinforced Thermoplastic Pipe is one kind of high-pressure plastic compound tube with the outer layer and liner are a PE80 or a PE100, the outer layer according to needs to be possible to choose the white color (on the ground against ultraviolet ray) or the black color (underground), the intermediate layer is the enhanced tape, the reinforced material may be the polyester fiber or the aramid fiber or so on. The pipes use many kinds of connection forms such as enhancement in-line coupling, swaging fitting, flanged join to connect, the RTP pipe general application temperature, or -42°C ~ 135°C. The max operation pressure may reach 32MPa most greatly

Technological research and development ability.

Our company’s product is under strict observation of the international ISO, the API standard, and the standard design manufacture. These standards are as follows:

- API RP15S “Qualification of spoolable reinforced plastic pipe”

- ISO TS 18226 “Plastic pipes and fitting – Reinforced thermoplastics pipe systems for the supply of gaseous fuels for pressure up to 4 MPa (40 Bar)”

- API RP 17B “Recommended practice for fixable pipe “

- SY/T6794 “Qualification of spoolable reinforced plastic line pipe”

- DIP 31.40.10.20-Gen Spoonable fiber reinforced plastic pipes

Specification Parameters

| DN / ITEM | 65mm 2.5in |

80mm 3IN |

100mm 4in |

125mm 5in |

150mm 6in |

200mm 8in |

250mm 10in |

300mm 12in |

Notes |

|---|---|---|---|---|---|---|---|---|---|

| OD | 90mm 3.5in |

105mm 4in |

125mm 5in |

155mm 6in |

180mm 7in |

250mm 10in |

310mm 12in |

365mm 14.5in |

|

| Max Delivery Lenghth (high way transportaion) |

800m 2625ft |

600m 1970ft |

400m 1310ft |

250m 820ft |

180m 590ft |

17.5m 57ft |

17.5m 57ft |

17.5m 57ft |

|

| Working Pressure | 2.6~4.5MPa 375~2100psi |

2.2~12.5MPa 320~1810psi |

1.7~10MPa 245~1450psi |

1.4~8.0MPa 200~1160psi |

1.1~6.8MPa 160~980psi |

1.0~10.9MPa 145~1580psi |

1.0~8.0MPa 145~1160psi |

1.0~6.0MPa 145~870psi |

The higher pressure RTP can be designed |

| Working | -40°C~85°C | The higher temperature RTP can be designed | |||||||

| Temerature | -40°F~180°F | The higher temperature RTP can be designed | |||||||

The following detections and tests could be done by us:

- Raw Material Density

- Raw Material Moisture

- Plastic Melt Index

- Tensile Test For Fiber

- Tensile Test For Enhanced Tape

- Tensile Test For RTP Pipe

- Bending Test

- External Pressure Test

- Long and Short Term Static Hydraulics Pressure Test.

- Short Term Bursting Test

- Thermal Stability Test

We have had the pressure piping design and manufacturing capacity and qualification may provide the pipeline design and may combine with the used international CAESAR, ANSYS, and the PE/PIPE software, carries on the flexible pipe arrangment stress analysis and the engineering design from the system of the part:

- Design of the composite pipe and the connecting structure.

- Analysis of structure stress

- Intensity analysis of long term static pressure

- Type selection and design according to the tension stress analysis for the flexible components

- Stress Analysis of pipeline

- Manufacturing in the factory and on-site service

- Failure analysis and solution for pipelines